![]()

|

Text By Evan Griffey

Photos By Evan Griffey & Robert Hardin

This article originally appeared in the Turbo & Hi-Tech Performance November 1995 issue and was reprinted with permission. For more info on Turbo Magazine check out their website.

|

| This nifty backpressure gauge from Blitz should prove a useful tuning tool. We plan to use it to check backpressure at different boost levels. |

We have had time to live with the Sentra in turbo trim and gladly report all is well - knock on wood. Our T-BAC III boost controller is set to provide 15 psi at the high setting, nine psi at the low setting and five psi when the unit is turned off. We'd say that the nine psi setting is used 60 percent of the time. We are impressed at how well the engine idles and its acceleration with and without boost pressure is a testament to the tuning talents of Jim Wolf Technology and the porting job executed by Bill Craddock Enterprises. The commute down Pacific Coast Highway has been interesting as the driver of a certain '80s Corvette could testify to. The car performs exactly as we expected, downshift, pull around traffic, trap the accelerator against the firewall and the SE-R leaps out of its skin. This is the kind of responsiveness we wanted. At 15 psi the tires start to spin at the top of third gear, making dicing between cars a concentrated effort. As we got comfortable with the car, we charted gas mileage and found we were 12 mpg short of where we were before the turbo installation. With the larger injectors and a more active right foot, we didn't expect the same numbers, but a 12 mpg deficit was a bit much. We also noticed a drop-off of vacuum at freeway cruising speeds. What should be 18 to 20 inches of vacuum is only 10 to 12 - the culprit is excessive backpressure. There is more exhaust gas hitting the turbine wheel than the wheel can move. As a result, the gasses back up into the engine and turbine speeds soar. This causes the turbo to make boost before the throttle plate and, more worrisome to us, was the excessive heat on the exhaust valves which is not good. Thumbing through a Blitz catalog, we found a backpressure gauge. We never heard of such a thing and gave the North American branch of the company a call. We now have one and plan to install it soon, it should prove a useful tuning tool.

|

| Seen here at the Brotherhood Raceway, the Sentra backed up its Palmdale numbers by running a similar trap speed. At the March 26th Battle Of The Imports the Nissan ran a corrected 13.69-second quarter mile at 99 mph. |

We had to get some real performance numbers so we took the Sentra to the March 26, 1994 Battle Of The Imports at Palmdale Raceway. With our esteemed technical editor Michael Ferrara at the controls and 6.0-inch slicks clawing the pavement, the Nissan faced the Christmas tree for the first time. The Sentra, which posts 15.8s at 88 mph in stock form, blasted to a 14.15 at 96.24 mph, which is a 13.69 at 99 mph effort when corrected for altitude. The 60-foot time was 2.252 seconds (uncorrected) and the run was made with the full exhaust system. Even with the slicks, Mike experienced wheelspin in First gear. The next run was made without the exhaust and the car seemed to run quieter. With a better handle on the car's launching characteristics, Mike had less wheelspin on his second run and believed he was on his way to a 13.8 uncorrected when the clutch gave up the ghost at half track.

When we originally chose the clutch combination for the Sentra, we had two goals in mind. First, we wanted to eliminate the slippage. This was accomplished by using a dual-diaphragm pressure plate built by Action Clutch. This worked, the only compromise was a much stiffer pedal. Our second goal was to retain the stock-like clutch engagement. Since we knew that a full-facing disc offers softer engagement than puck or button types, we used a stock replacement clutch disc. On the street this combo performed flawlessly. Unfortunately, at the strip the extra load created by the slick's ability to grip the pavement overwhelmed the clutch. Luckily, John Concialdi from Advanced Engine Management had an open spot on his truck and hauled our wounded warrior to AEM in Gardena, California. John was kind enough to get us back on the road in short order. He installed one of AEM's High-Performance Series (HPS) six-puck metallic clutches in the Nissan. The dual diaphragm unit features a heavy-duty pressure plate and a spring-center disc with 2100 pounds of clamping force. The HPS feels solid and performed flawlessly at the strip on street tires, but it has yet to tangle with slicks. Of course, this setup makes for harsher engagement but it is also better suited to the high horsepower aspirations of our project.

|

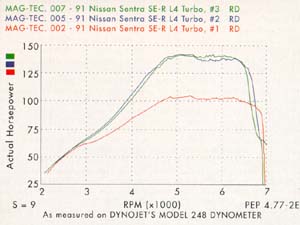

| Although our results at K&N's DynoJet dyno were tainted by a malfunctioning wastegate we were able to get some readings at nine psi. The Nissan produced 147.7 horsepower at our "low" setting. |

A follow-up session at Brotherhood Raceway on street tires backed up the car's Palmdale performance as we ran 98.88 mph. We only got three runs in and never really nailed the launch so the e.t.s were lackluster at best. The fact that the owner, and not hard-charging Mike Ferrara, was at the wheel had a little to do with it. One constant at Palmdale and Brotherhood was poor pull in Third gear.

We have always wanted to know exactly how much power the 2.0-liter was putting out. We eagerly awaited the installation of K&N's DynoJet chassis dyno and just as we were compiling the information for this story we got the green light. At the company's Riverside, California facility we tied down the SE-R and began testing. With the boost controller turned off we recorded 108.1 horsepower at 5300 rpm and 116.9 lbs.-ft of torque. This run netted three psi. We usually got five or six psi out of our "valet" setting. When we upped to boost to the low setting (nine psi) we got 147.7 horses at 5100 and 159.7 lbs.-ft at 4500. This was the correct boost level, but the boost needle wasn't responding as fast as it should have. As we moved to the high setting we discovered the gremlin. Even at the upper level we only got nine psi. The gremlin was a faulty wastegate. We disconnected the boost line to the wastegate and the turbo didn't spool wildly, it registered the same nine psi. Disappointed, we packed our bags and left Riverside with out tails between our legs.

|

| When the turbo is operating at its 15 psi maximum, the entire intake and fuel system systems are at their capacity. Since we plan on adding a bigger turbo we borrowed an intake from Jim Wolf Technology to prefab a fuel system featuring 50 lb.-hr MSD injectors. |

When operating at 15 psi, the turbo is maxed out, and as mentioned in the last report (Sept. '95) so is the Mass Air Flow sensor (MAF), injectors and the entire fuel system. Well it's no secret that we are nuts, so here we go again. The Serious Sentra's second iteration is coming. The battle plan calls for 50 lb./hr MSD injectors on a custom fuel rail, a larger fuel pump, a modified MAF sensor from JWT, and of course a turbo upgrade. Still in the early stages of planning, this turbo is going to be a hybrid T28 concoction from Chris Weisberg of Turbonetics. Again, we want to balance top-end power and responsiveness but want more lung capacity in Third gear and lower e.t.s at the track.

The original concept of this project was to make a turbo SE-R from readily available parts. The T25 is just that as many shops have them laying around from Z-car customers who have stepped up to a sport turbo. the idea back then was to run a non-intercooled system at five psi. With the SR20DE's resistance to detonation, we believe this is a viable low-buck option, with proper tuning of course. Nissan Motorsports' introduction of lower-compression cast aluminum pistons, 1.2mm metal head gasket and the all-important cast manifold make the transformation even easier.

A Stage II setup would include an intercooler and maximum boost pressure would be nine or 10 psi. This would make a lively and reliable car to say the least. We feel any additional boost with a T25 would create excessive backpressure outlined earlier in this article.

It is our hope that the Sentra saga will serve as a learning experience for anyone attempting to build a complete, custom turbo system for a car not originally offered in turbo trim. To those of you out there... May the force be with you.

| The Source | |

|---|---|

| Advanced

Engine Management 15606 S. Broadway Center Gardena, CA 90248 (310) 327-9336 |

Essex Performance 6 Sunnen Dr. St. Louis, MO 63143 (314) 644-3000 |

| American

Racing Equipment 19067 S. Reyes Ave. Rancho Dominguez, CA 90221 (310) 635-7806 |

K&N 561 Iowa Ave. P.O. Box 1329 Riverside, CA 92502 (800) 858-3333 (909) 684-9762 |

| BFGoodrich P.O. Box 19001 Greenville, SC 29602-9001 |

MSD, Autotronic Controls 1490 Henry Brennan Dr. El Paso, TX 79936 (915) 857-5200 |

| Blitz-Yamaco #3 A-11240 Bridgeport Rd. Richmond, BC Canada V6X1T3 (604) 244-7261 |

Turbonetics 5400 Atlantis Ct. Moorpark, CA 93021 (805) 529-8995 |

| (BCE) Bill Craddock Engineering 10808 Foothill Blvd Ranch Cucamonga, CA 91730 Phone: (909) 944-8097 Fax: (909) 944-8933 |

Jim

Wolf Technology 212 Millar Ave. El Cajon, CA 92020 (619) 442-0680 |